- Simple capture of business rules with a click of the mouse: designed for non-technical users – no programming skills required

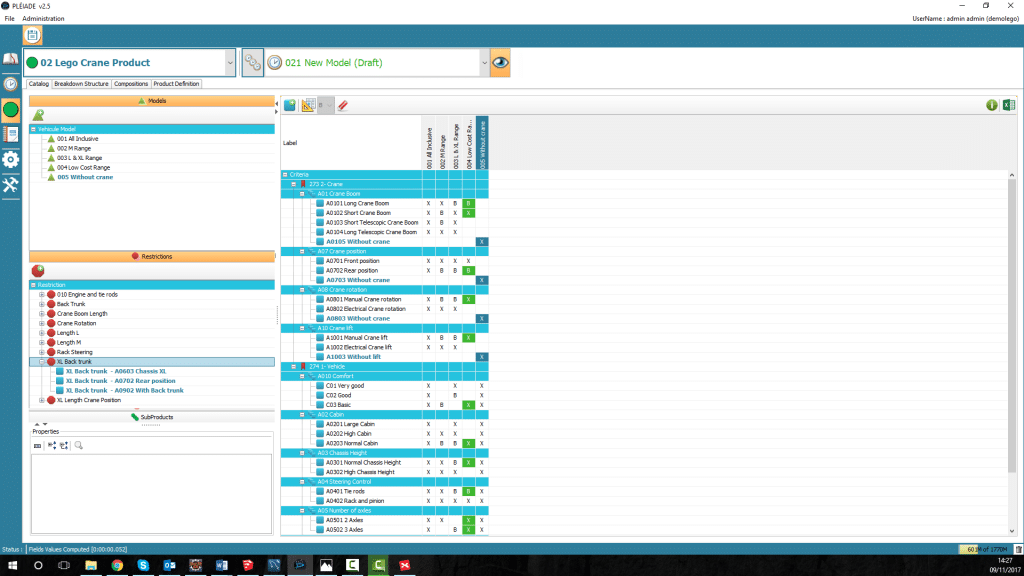

- Option: authorizations and restrictions

- Item rules-based configuration

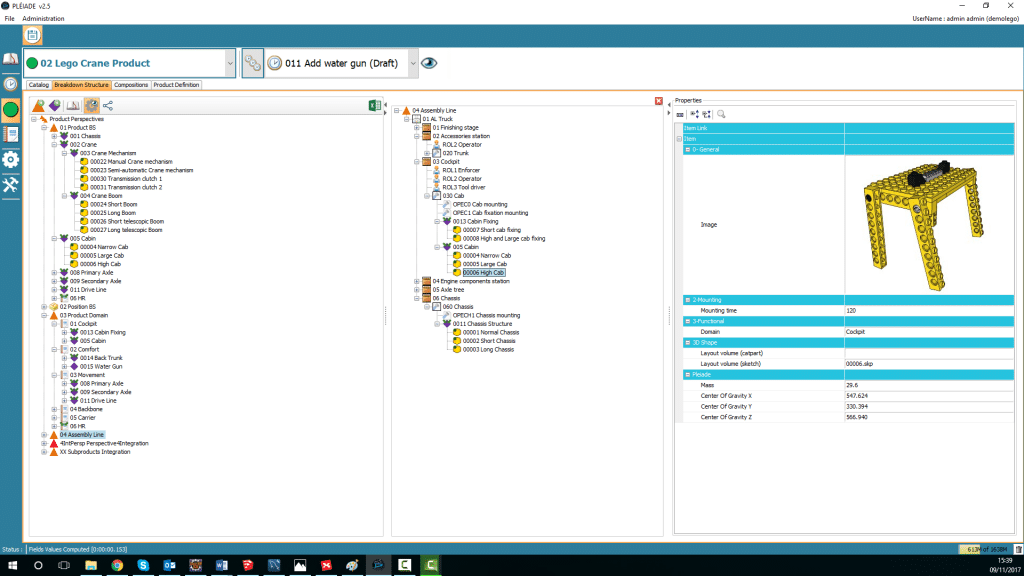

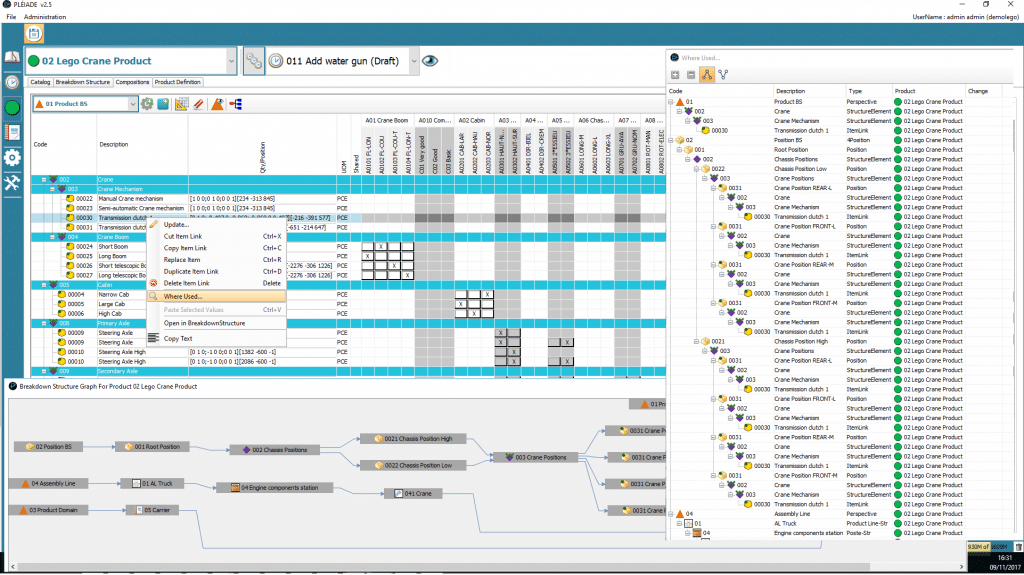

- Complex system modelization (product/sub product)

- System and product constraints

Pleiade

Product Line Engineering In Advanced Diversity Editor

Pleiade saves you time and effort

It makes configuration documentation so easy that it does not require special skills or staff support

It enables product configuration aligned with product line requirements

It’s ultra-quick, filtering about 200 000 lines of BOM with 1060 combinations in the blink of an eye

It allows product customization

- Easy items differentiation between product family range and customer product definition

- BOM comparison

- BOM realignment vs. current product baseline

It enables BOM and operation export to ERP

Pleiade empowers real-time collaboration

It provides your cross-functional teams with shared views of BOM management applied to your unique business unit data model

It tracks modifications through a simple and powerful configuration management process

It tracks product evolution through planned group change

It uses common product architecture—master data of the product line

- Catalogs of product lines: a list of models with possible variants and their constraints

- Multiple views or perspectives: such as engineering, manufacturing, Maintenance, Repair and Operations (MRO), and so on

- Composition: configuration rules

It uses Digital Mockup (DMU) integration based on part positioning

- Parts position computation in multi-coordinate systems

- Complete or partially configured mock-up visualization : multiple Computer-Aided Design (CAD) systems and viewers available

- Center of gravity for configured product

It manages user access rights according to business role and responsibilities in the product breakdown structure

Pleiade improves your quality and standardization

It monitors product line design progress and quality, using Artificial Intelligence (AI) techniques to master complexity

- Identify inconsistency within product structure

- Propose rule simplification

- Improve product structure completeness

- Avoid unnecessary combinations study

- Provide analysis of variant combination coverage

It automates attribute calculations (e.g. mass or cost calculation) with user-defined formulas in an Excel-based format

Where Pleiade adds value to

Your sales force

Keep sales department aware of what can or cannot be proposed

Assist sales department to build user-friendly, tailored configuration for customer with accurate pricing

Your operations

Engineering

- Reduce time and skill complexity to create and maintain product documentation

- Drive engineering forces for a range of configurations identified by the marketing department

- Standardize customization

- Monitor completion of your product configuration

- Validate not just specific configurations but the whole product range

Manufacturing

- Design product and process at the same time

- Keep the process standard even if the final product is highly variable

- Design workstations, operations and tools independently but in sync with engineering structure

Support

- Anticipate spare parts supply

- Track vendor information independently of engineering and/or manufacturing management

Your executive and management

Executive

- Design, manufacture and sell large volumes of highly variable products

- Offer more to your customers while reducing internal complexity

- Keep manufacturing prices low

Project Manager

- Reduce time and skill complexity to create and maintain product configuration

- Manage change orders on demand and their chronology

Chief Information Officer

- Easy deployment : automatic update, access rights management, out-of-the-box or customized profiles, LDAP authentification

- Ease of use : such as multilinguals and large display

- Data model customization : subtypable, user-defined attributes through text, list, image, boolean and URL datatype)

- Migration and data initialization through tabular files